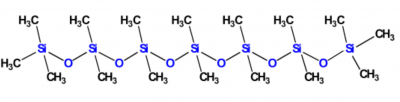

Description

Element14 PDMS 1000 is a linear polydimethylsiloxane polymer with a kinematic viscosity of 1000.

Element14 PDMS fluids can stay in liquid form at conditions that cause polymers to become greases, waxes or solids. Because the viscosity of Element14 fluids change with very little temperature, pressure, mechanical stress or chemical exposure, they can excel in applications that require fluid properties in harsh environments.

The silicone-to-oxygen bond in Element14 PDMS fluids is much stronger than the carbon-to-carbon bond. As a result of this structure, the silicones exhibit:

- Unusually low viscosities at high molecular weight

- Outstanding high and low temperature stability

Features & Benefits of Element14 PDMS 1000

- High and low temperature stability

- Oxidative stability

- Chemically inert

- Low flammability

- Low surface tension

- Shear stability

- High compressibility

- Low vapor pressure

- Low odor

- Soft, smooth skin feel

- Non-oily feel

- Spreadability

- Low coefficient of friction

- Lubricious

Applications

- Heat and mechanical transfer fluid, Hydraulic fluid, Electrical insulating fluid, Water repellent, Polish ingredient, Mold release agent, Lubricant, Anti-foam, Personal care ingredient, Textile spin finishes, Paints and coatings additive

Typical Properties

| Properties | Value |

| Viscosity cSt | 1000 |

| Appearance | Clear, colorless liquid |

| Specific Gravity at 25°C | 0.97 |

| Refractive Index at 25°C | 1.4 |

| Flash Point, Open Cup, °C | > 302 |

| Pour Point, °C | -47 |

| Surface Tension Dynes/cm at 25°C | 21.3 |